PLANT

The company plant is located at Rajkot-India. The plant is fully equipped with all facilities for Design,Tooling, Manufacturing and Inspection.

MACHINERY

The company has various machineries, such as Power Presses of capacity up to 100 Tons, Automatic Turning machines for (Fin) face turning; Vibro finishing machines & shot blasting m/c etc. Few details of the facilities are given below:

HIGH CAPACITY POWER PRESSES

The initial form of the cage is based on the type of the bearing. Such form is generated by respective tooling, on the high capacity press.High Capacity power presses are used for initial processes of blanking and cup embossing etc. The machines are provided with high quality Tooling which enables consistency in form configuration.

AUTOMATIC TURNING MACHINES FOR CAGE FACE TURNING

Company has a series of automatic face turning machines, auto holding system. These are used for fine turning of the face of the cage, before they are processed for pocket hole punching. The facility enables consistent quality in height control for the cages.

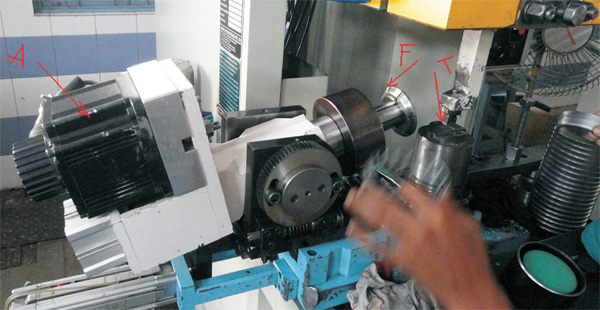

For the TRB or CRB / Needle bearing, the cage will be provided with pocket holes, using a press machine.AUTOMATIC CNC – INDEXING PRESS MACHINES

The pockets must be provided in equal spacing, so that the load distribution thro rollers spacing, will be uniform.

The company has a series of automatic CNC indexing type presses. The CNC indexer will enable perfect equidistancing of the pockets.

MECHANISM OF THE INDEXING PROCESS

The machine is fitted with a CNC driven Indexing system, which enables stopping the tool at equal intervals in the circumferential rotation

A= CNC indexing system; F= Cage holding fixture; T = Tooling ( Die & Punch)

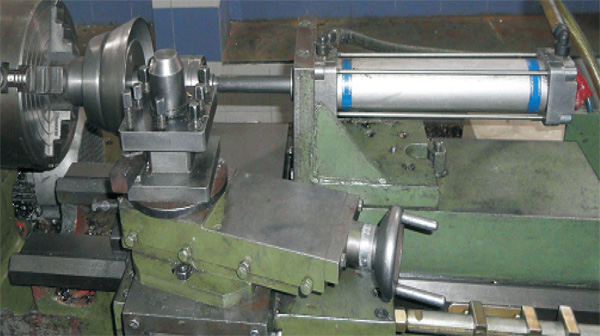

AUTOMATIC CAGE BULGING MACHINE

After the Coining process, cages are deformed / bulged in pneumatic press. This process enabled the assembly

of cage with rings of the bearing.

Due to our precise tooling and machinery, bulging is uniform in each cage and throughout the batch

production.

SHOT BLASTING MACHINE

After the Bulging process, the cages are finished in Vibro finishing process for Deburing & then shot blasted for

achieving the requisite finish.